In March 2019, Epson officially opened three nozzles to China market: L1440-U2, F1440-A1 and the large nozzle S3200. Each nozzle has its own emphasis and its own characteristics. In one year of research and development and market testing, we have obtained good reputation and excellent performance as always. It achieves very ideal application effects in different application schemes and different ink adaptability. In particular, the L1440-U2 print head is becoming a powerful engine for large-format printers made in China. It is also the focus of this article.

Excellent companies must maintain excellent traditions!

Excellent traditional craftsman spirit

Epson is familiar to China market. But in fact, this company in Japan is called Seiko Epson Corporation, and it is a global leader in digital imaging technology innovation. Epson as we know it has watches, printers, robots, projectors, scanners, electronic components, etc. There are more than 100 companies worldwide with more than 72,000 employees.

Since its founding in 1942, Epson has produced a large number of pioneering products leading a new era of technology. In the 1960s, the world’s first quartz electronic watch was produced. In the 1980s, it entered the field of industrial robots. In the 1990s, it entered the projector and printer market. At present, innovations in the four business areas of inkjet, vision, wearable products and robotics have been formed. In the field of inkjet printing head is an indispensable cornerstone.

Epson’s advanced digital and automated print head production line is a strong guarantee for its print head quality and excellent product rate.

The powerful power engine brings unlimited possibilities to printing equipment!

L1440-U2 excellent technical parameters

There are already a lot of parameters of each nozzle in the network and official releases, but they are basically the same version, as shown in the following table:

But the interpretation of these data is very few. This article attempts to share the interpretation of these data with everyone.

Obviously L1440-U2 is a 1-inch head. The goal is for UV inks. As for you to use other inks and solutions, it is your business.

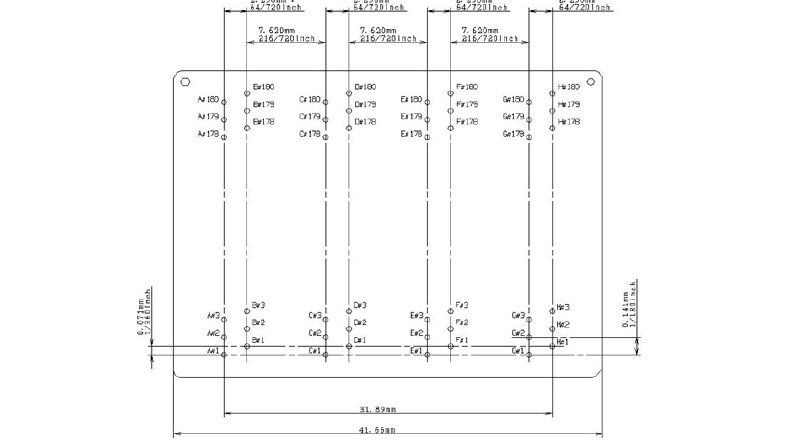

1.In terms of accuracy. In terms of accuracy, it often causes some misunderstandings. The accuracy in the print head parameters should be npi, not dpi, and npi should be the physical accuracy of the print head, that is, the number of nozzle holes per inch. L1440-U2 has 180 nozzle holes in a row and the length is 1 inch, then The accuracy should be 180npi. When the double rows are arranged in a group, the accuracy should be 360npi because of the misalignment. Undoubtedly, if you do 8 channels, obviously it can only be 180npi. To achieve higher accuracy, more nozzles or more passes are required.

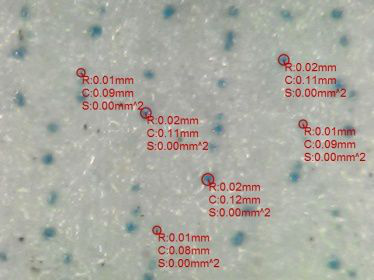

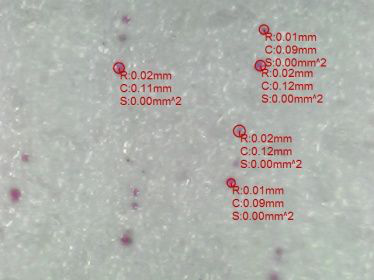

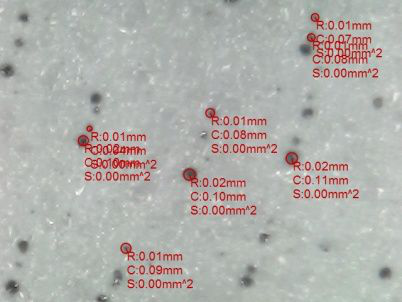

dpi is the imaging accuracy, which is related to the nozzle hole distance of the nozzle itself and also related to the spreading coefficient of ink droplets after imaging. The spread coefficient of different inks is obviously different. Due to its short curing time, UV ink has a small spreading coefficient, the final imaged ink drop diameter is small, the ink layer is thick, the accuracy is higher, and the coverage rate is better under the same ink volume per unit area. Therefore, the imaging accuracy of the same nozzle with different inks and different materials is different. The original spherical diameter of a 5pl ink drop is: 0.00212mm; if the spreading coefficient is 1.05, the diameter of the imaging point is 0.002226mm. In the actual test imaging, due to the high initial velocity of the ink droplet, its spreading coefficient becomes larger. The measured ink droplet is relatively stable at about 0.02mm, the actual large dot is 0.02mm, and the small dot is 0.01mm.

The upper left is cyan; the upper right is magenta; the lower left is magenta; the lower right is black. The hole distance of L1440-U2 is: 180npi=0.141mm; 360npi=0.071mm; if we need to obtain 1440dpi image quality, then we need at least: 8pass and 4pass; at this time, we calculate the amount of ink per square meter is still not enough, so we will definitely use large ink droplets in gray to increase the coverage rate. A picture with insufficient coverage cannot achieve the ideal saturation.

- Ink passing ability. This data is rarely used by authors, what does it mean? Very simple, it is the maximum amount of ink that passes through the nozzle in a unit time. The throughput of L1440-U2 ink is 1036.8ml/hour. Such a huge ink throughput can fully meet the speed requirements of various devices today. But under normal circumstances, we cannot reach this value. The reason is related to many factors: the board card, ink, movement method, required accuracy, and color density per unit area all limit the ink throughput.

- For viscosity. L1440-U2 is regarded as medium to high viscosity. For ink, it should be relatively adaptable.

- The initial linear velocity of ink droplets. The initial linear velocity of the ink drop is 7~8 m/s; this parameter determines the height of the print head from the printing medium and the design speed of the carriage. Of course, it must be designed to match the ignition frequency of the nozzle.

- Ignition frequency. Single point 40khz, multiple points 22khz. How much the ignition frequency can be used is greatly related to the ink, ink circuit system, stepping system, rack design and materials used by various equipment manufacturers. The fact is very clear, but it is very difficult to make matching inks with high ignition frequency and small ink droplets.

- Other data such as acid and alkali resistance, theoretical life of nozzles, etc. still require close communication between equipment manufacturers and Epson and specific use according to usage scenarios.

L1440-U2 development trend

At present, many manufacturers in China have already launched corresponding equipment, and they have performed well in almost all kinds of applications, especially for multi-layer printing on ultra-transparent stickers with very high requirements, showing their strong market dominance capabilities.

With the pursuit of many manufacturers in the market, we have reason to believe that this print head will become a classic print head in the market. At present, Guangzhou Dingyin, Guangzhou Hongyue, Guangzhou Jingcai, Guangzhou Laili, Shanghai WER-CHINA, Shanghai Heimai, Shanghai Aowei, Shanghai Cairui and many other companies are in the market with multiple solutions and models of large-format printing equipment. EPSON L1440-U2 is pushing the UV market to new heights. The future will be more anticipated.

Daily use and maintenance of nozzles:

- Do not touch the nozzle of the nozzle to prevent oxidation.

- When installing, the nozzle of the nozzle must be aligned and cannot be inserted hard. If the pinhole is not inserted properly, the nozzle will not work normally.

- The nozzle of the nozzle cannot enter ink , Cleaning fluid, etc., the contaminated socket can be cleaned with alcohol.

- The nozzle must maintain a good heat dissipation environment during use, otherwise the nozzle circuit is easily damaged.

- The damage to the nozzle circuit part by static electricity is very serious. When printing the board, the operator must remove the static factors, such as wearing anti-static gloves.

- If the print head is disconnected during the printing process, the printing must be suspended for the suction head. If the print head is seriously clogged, the nozzle can be cleaned with cleaning fluid, and then The ink is sucked out.

Note: the severely clogged nozzles will cause color difference after cleaning.

- Use the ink suction function and cleaning function provided by the printing program to ensure that all color nozzles will regularly suck ink during printing.

- After printing, Seal the protective film on the surface of the nozzle.

- The equipment using solvent-based ink will encounter the trouble of plugging.

The first reason for the plugging is that after the ink solvent evaporates, the ink particles condense in the nozzle, causing the nozzle to block; The second reason: There are impurities in the ink, or react with a certain solution agent to generate foreign matter, which is blocked in the nozzle.

Preventive measures: Use filters and other devices to prevent the ink cartridges from entering impurities.

Because a certain color of ink is not sprayed for a long time or the temperature of the nozzle is increased, the ink in a static state is dried and agglomerated on the inner wall of the nozzle, and if it cannot be cleaned in time, the nozzle may not be cleaned smoothly when its dryness is severe. Therefore, the nozzle should be cleaned frequently. The methods to prevent nozzle clogging are as follows:

- The nozzle voltage is not easy to be too high to prevent the inner wall from drying due to the heat of the nozzle.

- The ink viscosity is not easy to be too large.

- The nozzles that are not suitable for a certain color for a long time should be cleaned in time.

- When the nozzle is not spraying To protect.

Shanghai WER-China Industry Co., Ltd is a professional manufacturer for digital printers in Shanghai China, set up in 2009, WER has become one of the most reliable manufacturers of digital products in China. At present, WER concentrates to develop, manufacture and market digital printing products, for example, flatbed UV printer, DTG T-Shirt printer, textile printer, sublimation printer, ECO solvent printers, phone case printer, large format printer and printing consumable etc. WER headquarters (Factory: Shanghai Spring Digital Technology Co., Limited), with 3000m2 plots and over RMB10 million invest, is located in China old industry base. WER products have been exported to more than 50 countries and regions all over the world since found. With the export business development, for the beginning only sell XARR128 head printers, to the current we have been succeeded in making and selling various type of print head printers, such as flatbed UV printer, DTG T-Shirt printer, belt textile printer, sublimation printer, phone case printer, high-resolution EpsonDX5/DX7 head Eco solvent printers and SEIKOSPT1020, SEIKOSPT510, KONICA Minolta512 head wide format solvent printers, enrich product types to meet different customers’ demand. With the stable quality and the competitive price, the brand of “WER” has been becoming the first choice of customers in some countries.

WER always insists on market demand for direction, enhancing technology innovation, management innovation, marketing innovation, and service innovation. At the same time, introduce the high-tech talents with high salaries, improve WER core competition; WER wins market and customers with high quality, good service, and sincere attitude. Client purchases WER product, not only make money and gain success, for more come true mutual progress and mutual development. In order to supply all-sided services and establish a good cooperation partnership with our importers, WER also provides some products that are related to the advertisement industry, Like PVC flex banner, one-way vision, adhesive PVC vinyl, mesh, block out banner, cutting plotter, cold laminating machine, other peripherals and etc; only for supporting client’s business and saving purchase cost. With the idea of putting CUSTOMER FIRST and SERVICE FOREMOST; the high-quality product and good credit standing have become WER value concept. Pursue excellence, Keep enterprising, WER is dedicated to providing customers with high-quality products and perfect service. Strive to create an international Well-known brand in the digital printing industry.

Recent Comments