Screen printing is developed from the stencil printing method and belongs to the category of stencil printing. In screen printing, the screen is stretched on the screen frame to make it tightly fixed, and the screen printing plate is made by manual engraving or photochemical plate making. The traditional method is hand-made, and the photochemical plate-making method is more commonly used in modern times.

- Process points of screen printing

- The printed pattern should have good adhesion and cohesive force, and it is not easy to fall off.

- The printed pattern should be clear, the edges should be clearly demarcated, and there should be no blurring.

- The printed pattern should be evenly inked, and there should be no shades of difference or discoloration.

- There should be no defects such as pinholes, bubbles and net marks on the printed patterns.

- The position of the printed pattern should be accurate and there should be no overprinting.

- The printed product is not allowed to have size enlargement defects, and there should be no ink film cracking and ink bleeding.

- The whole printing should be clean, free of dirt and ink leakage.

- The image should not be deformed and should be the same shape and size as the original.

- The pattern must not have any defects such as ink spraying or flying ink.

- Principle and equipment of screen printing

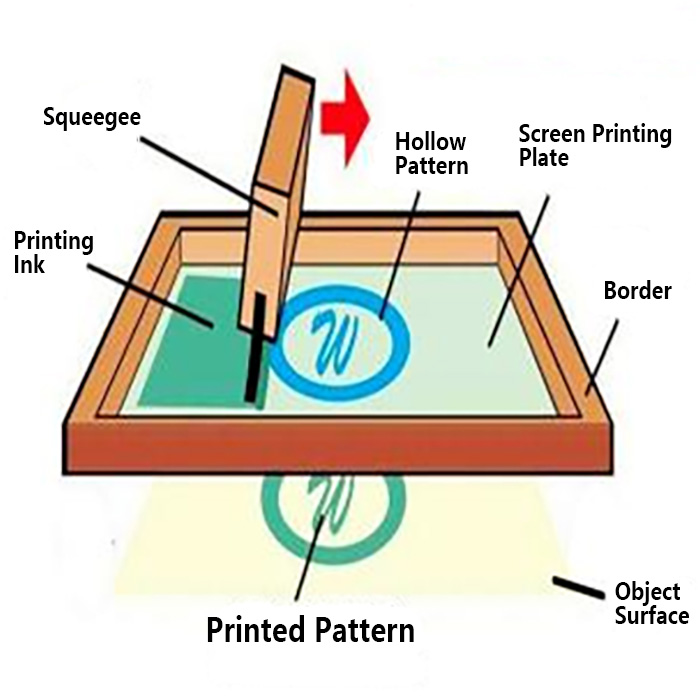

Screen printing is developed from the stencil printing method and belongs to the category of stencil printing. In screen printing, the screen is stretched on the screen frame to make it tensioned and fixed, and the screen printing plate is made by manual engraving or photochemical plate making. The traditional method is hand-made, and the photochemical plate-making method is more commonly used in modern times. Photochemical plate making method uses photosensitive materials to make a screen printing plate by photo making, so that the screen holes of the graphic part of the screen printing plate are through holes, and the screen holes of the non-graphic part are blocked. Put the screen printing ink into the screen frame, and press and scrape the screen frame with a squeegee. At this time, the ink is transferred to the surface of the steel drum through the mesh of the image and text part, forming the same image and text as the original. .

When printing, pour the ink into one end of the screen printing plate. The ink will not leak on the steel drum through the mesh without external force. When the ink is scraped by the squeegee at a certain inclination angle and pressure, the ink The screen is transferred to the surface of the steel drum under the screen, so as to realize the reproduction of the image.

Simple screen printing equipment, convenient operation, simple printing and plate making, low cost and strong adaptability. It is not only suitable for printing on the top surface of steel drums, but also for printing on the curved surface of steel drums, and it is also easy to realize automatic production.

There are two types of steel drum screen printing: flat printing and curved printing. Flat printing is used for printing on the top of the barrel, and curved printing is used for printing on the barrel.

Plane printing equipment is relatively simple, and many companies use manual holding plate printing, which is relatively simple to operate. The platform flat screen printing machine has a relatively simple structure and is composed of a barrel feeding system, a printing mechanism, and a barrel discharging mechanism. The screen used for printing is installed horizontally on the frame of the printing plate. The frame is equipped with a mechanism and a squeegee to control the up and down movement of the printing plate. Each time a piece is printed, the screen moves up and down once, and the squeegee moves back and forth once at the same time. The worktable has a horizontal lift type and a sliding table type printing frame, both of which have the characteristics of stable work and high overprinting accuracy.

When the surface of the cylindrical steel drum is printed, the cylindrical steel drum is fixed on the printing table and is in line contact with the printing plate; the screen printing squeegee is fixed, the printing plate moves horizontally during printing, and the steel drum performs synchronous rotation at the same time; the ink is on the screen The printing squeegee is transferred to the surface of the steel drum under the pressure of the printing squeegee to complete the printing. After printing, remove the steel drum and install another steel drum for printing. It is worth noting that during the entire printing process, the screen printing plate is always in line contact with the surface of the steel drum.

- Use and maintenance of screen printing machine

- Key points of screen printing machine operation

(1) The cylindricity of the surface of the steel drum is required to be high. If the cylindricity of the steel drum cannot be guaranteed, the purpose of printing will not be achieved. The smaller the circumference of the steel drum, the higher the cylindricity requirement.

(2) Scraper center setting. When the scraper is installed, its midline passes through the vertex and must coincide with the diameter of the steel drum. If this condition is not met, good printing results cannot be obtained even if other conditions are met.

(3) Imprinting. Although the printing pressure of screen printing has nothing to do with the printing surface and the printing plane, the printing pressure must be controlled to a minimum. Especially in curved screen printing, if the printing pressure is too large, the condition of the squeegee will deteriorate, which will have a bad effect.

(4) Selection of scraper rubber. Generally, a sword-shaped squeegee strip is used for curved surface printing.

- The maintenance of the screen printing machine The screen printing machine has fast and balanced printing action, precise positioning, arbitrary selection of printing stroke, with micro-movement division table, can provide precise screen adjustment effect, squeegee, ink return pressure angle can be Adjustable, equipped with powerful air motor, prevent board displacement and other advantages. But no matter how advanced the equipment is, if it is not well maintained and maintained, its service life and expected results will be greatly reduced.